30 Years of Experience

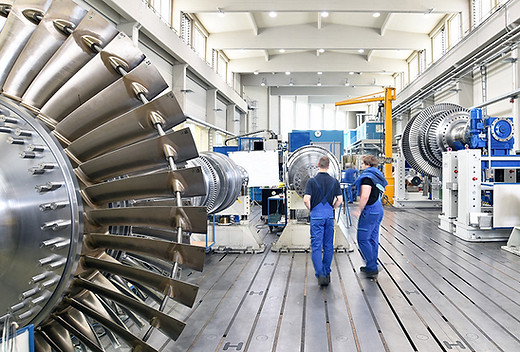

Providing Maintenance & Repair Services for All Power Generation Turbines and Oil & Gas Equipments.

Keck Energy Libya provides comprehensive planning and implementation services for maintaining and repairing Power Generation and Oil & Gas Equipment worldwide. With partnerships that work with top OEMs such as GE, Siemens, ABB, BBC, and Westinghouse, we offer certified service personnel with advanced technical expertise for Gas Turbines, Steam Turbines, and Boilers. Our Oil & Gas equipment partners include leading compressor manufacturers, Storage Tanks, Pressure Vessels, Metrology, fiscal, custody transfer, blending Process Analytical and Continue Emissions monitoring, SCADA systems, Drill Pipe and Drill bits, Pipeline cleaning and testings, Flow Pipes, Surface Monitoring & Maintenance, Downhole Solutions, Well Intervention Tooling, Reservoir, Geological and Geophysical software, and a host of other services.

Providing parts and repairs for all major USA & European Turbine OEMs

About Us

Keck Energy Libya is a leading provider of maintenance and repair services for all power generation turbines In Libya. Our team of international experts has decades of experience in gas turbines and combined cycle plants for power generation and oil and gas applications.

Led by Mr Richard Keck, who worked for 25 years as a Senior Executive for GE and the engineering leader for all the Upstream businesses of GE Oil & Gas, Holding 12 US patents in aero-derivative gas turbine product development, with decades of Experience in Aviation, Power Generation and Oil & gas he led more than 2,000 employees worldwide while at GE.

For five years, he was also the Engineering leader for all the upstream businesses of GE Oil & Gas.

His expertise includes managing $300M plus budgets, focusing on reducing cost and increasing operational efficiency. Recognized for the ability to identify and capitalize on opportunities for innovation

He was also responsible for all engineering aspects of Surface, Offshore, Drilling, Artificial Lift and Subsea Platforms, including advanced technology, new product introduction, requisition, service engineering and customer support.

Mr Keck led a global 500-plus person team responsible for engineering design, development, requisition, and service functions for GE Energy's Aero Energy Division, a $3 billion business focused on the production and the service of aero-derivative and reciprocating engines for Industrial, Marine, Oil & Gas, and Power Generation applications.

Our team deeply understands power generation turbines' complex engineering and technical requirements; we pride ourselves on providing our clients with high-quality, reliable, cost-effective solutions.

Our team of international experts in OEM gas turbines and steam turbines can perform all oil services and technical support, both internationally and locally.

We specialize in offering customized solutions tailored to the specific needs of our clients, ensuring maximum efficiency and performance of their power generation turbines. Whether it's regular maintenance, repairs, upgrades, or overhauls, our team has the technical know-how and expertise to handle everything.

At Keck Energy Libya, we prioritize safety, quality, and customer satisfaction in all our operations. We are committed to using the latest technology and best practices to deliver top-notch services to our clients, helping them achieve their business objectives.

Our Services

Power Generation Products and Services

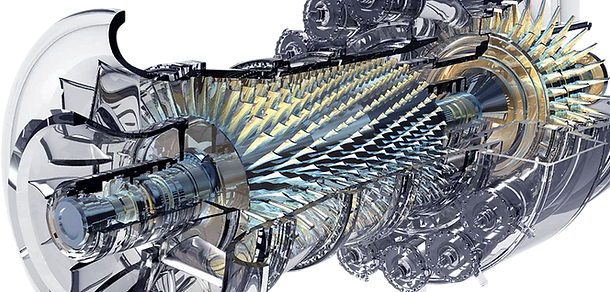

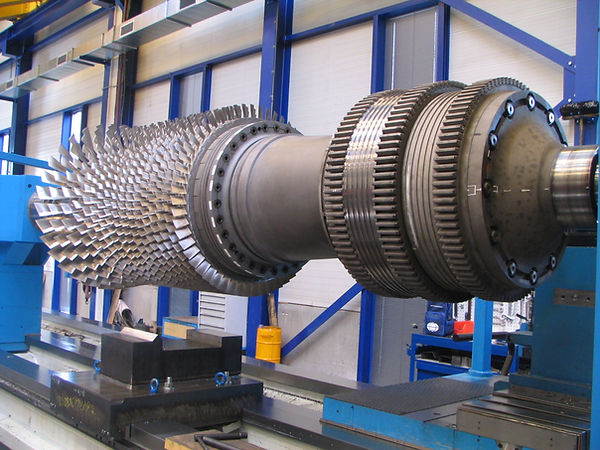

Gas Turbines Overhauls

KEL gas turbine services can help keep your gas turbine running reliably and efficiently over its entire lifecycle. We offer an overhaul service for all types of gas turbines and have over 30 years of experience. We offer a variety of overhaul solutions based on your needs and have access to engineering specifications and implement the latest original equipment manufacturer (OEM) design improvements in each overhaul.

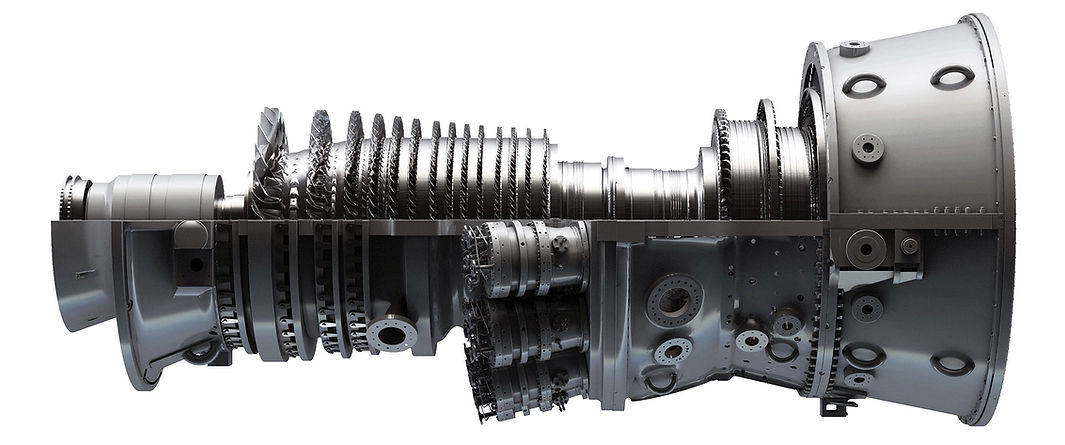

Gas Turbines Parts

We provide high-quality parts that ensure the optimum performance of your gas turbine assets that meet or exceed OEM performance for a variety of heavy and light industrial gas turbines.

New life for your gas turbine.

KEL has access to the largest full-line supplier of aftermarket replacement parts for virtually all Gas turbine models, With a complete line of parts for GE & Westinghouse Gas Turbines.

High quality

We supply gas turbine components for many different makes and models. We usually provide a more cost-efficient and faster alternative to the OEM. Our commitment to high quality and fast turnaround ensures your unit returns to operation with reliable performance and high availability.

Replacement parts

While our repair processes focus on lifetime extension, some parts must be replaced in order to restore your equipment and optimize performance. We supply new components to both the hot and cold sections, including blades, vanes, liners, and hot-gas casings. We have the capability to incorporate improvements to the original design based on our engineering expertise and the specific needs of our customers.

Keck Energy Libya is the sole Agent for USA Turbine Services, LTD

Component repairs

KEL provides gas turbine component repairs for customers in the power generation, industrial, and oil & gas markets. With state-of-the-art repair and coating facilities, we are dedicated to developing innovative solutions that help extend the efficient operation of our customers' gas turbines.

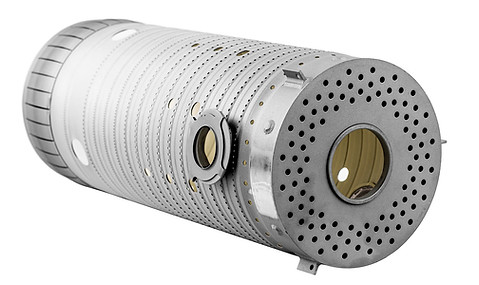

Combustion Tuning

Combustion DLN tuning services are needed during basic unit start-up and periodically any time after combustion and hot gas flow hardware gets changed out. Furthermore, combustion tuning might help you achieve your goals for work flexibility.KEL can join you on your work site or connect remotely to ensure DLN tuning services. Our combustion engineer utilizes site CEMS emissions data & CDMS combustion dynamics data. This process is crucial to assess the condition of the gas turbine and system. It makes changes to boost emissions & combustion dynamics to reduce combustion hardware stress stages.

Accessory repair

KEL offers complete manufacturing cycles for all stationary accessories and parts, such as nozzles and shrouds; regardless of size, combustion type, or fuel source, we provide gas turbine accessories repair with a single integrated solution that simplifies the supply chain, ensuring the delivery of equipment on-time. Our experienced engineers analyse all gas turbine operational factors to develop cost-effective accessory repair service programs aligned with control, combustion, thermal emission spread, and life extension targets.

Technical services include Dry Low Emission (DLE) repairs and dedicated mapping technicians to help you increase efficiency, minimise maintenance costs, and reduce downtime.

Hot gas component repairs

At KEL, we possess the technical expertise and extensive component inventory to assist you in restoring your unit's performance through our Hot Gas Path parts repair services. Our capabilities span across all Hot Gas Path parts, including Buckets, Nozzles, and Shrouds, allowing us to maximize their performance potential. We offer a range of services, such as Hot Gas Path Parts inspection, repairs, and coatings, to ensure that your components are operating at their best..

Repairs to extend component life

We provide gas turbine component repair services for the power generation, industrial, and oil & gas markets. With state-of-the-art repair and coating facilities located around the world, we use advanced technology to develop repair solutions that cater to our customers' budgets and timelines. In addition to our extensive range of repair services, we offer a broad portfolio of gas turbine repair development services aimed at prolonging component life and reducing maintenance costs and delays. Our global engineering team is dedicated to implementing innovative repair and refurbishment techniques to support our component repairs and coatings.

Fuel nozzles repairs

Our company offers a Full service for Gas Turbine Fuel Nozzle repairs, including comprehensive testing approved by OEMs. With our specialized knowledge and extensive experience in overhauling and repairing Gas Turbine Fuel Nozzles, we strive to enhance their performance and life cycle wherever possible. Our expertise spans a wide range of gas turbine models, sizes, combustion types, and fuel sources, enabling us to provide efficient and effective repair solutions

Field and site services

As an experienced provider of field services, KEL has extensive resources in servicing multiple gas turbine product lines; aero-derivative, light and heavy industrial gas turbines, oil & gas equipment, components and accessories

On-site repairs

Rotors, casings, fuel nozzle, and weld repairs can often be carried out during a major overhaul as direct on-site repairs.

Critical areas examined during on-site repairs include compressor blades, rotor journal, and turbine wheel conditions. In addition, Non-Destructive Testing (NDT) blades, dovetails, blade migration, and balance weight locations are all inspected to the latest OEM specifications.

KEL's reputation for responsiveness and innovative solutions is the foundation upon which our field and site services have been built. Our range of services includes outage planning, safety planning, inspection, overhaul services, full-time engineering support, project implementation, parts supply, and more. We have the capability to perform anything that can be done at our repair facility on-site.

Our primary focus is on ensuring the overall outage schedule, technical performance, and cost management are managed effectively, enabling us to complete your maintenance event on time and within budget. Our extensive field service experience enables us to provide support to your maintenance planners, outage managers, and project engineers in delivering outage services that meet or exceed your expectations.

Steam Turbines Overhauls

Steam turbines may require maintenance, repair or upgrades for various reasons; planned maintenance, unplanned outages, reliability issues, or improved performance.

Over the years, KEL has understood the significance of paying attention to our customer's requirements and offering appropriate solutions. We have established an extensive range of steam turbine services, capabilities, and products to fulfil these demands.

KEL is capable of offering the following services:

-

Planning maintenance schedules

-

Designing and calculating turbo sets

-

Planning I&C and electrical equipment for turbines

-

Designing BOP systems and their components

-

Preparing comprehensive technical documentation such as P&I diagrams, measuring equipment lists, electrical consumer lists, piping/valves & fittings lists, system descriptions, and operating and maintenance instructions.

Design Engineering

Preparation of manufacturing documentation of various turbine subassemblies:

-

Drawings (modelling in 3D, drawing extraction in 2D)

-

Part lists

-

Test plans

-

Instructions

-

Declarations of incorporation

-

3D measurement of unknown subassemblies

-

Material selection

-

Definition of machine tolerances

-

Diagrams

Design engineering also has an additional application area which involves providing support during production and installation stages. This includes measuring the parts concurrently with disassembling defective components, and designing a 3D model. The information gathered from this process is then utilized to program machine tools, ensuring prompt supply of spare parts.

Rotor Life Extension

Keck Energy Libya offers end-of-life solutions that are proven and reliable for ageing fleets, particularly for heavy-duty gas turbine frame B, E, and F class, as well as mature Westinghouse units. These solutions have been designed to meet or surpass the standards of the original equipment manufacturer and recommended end-of-life specifications.

Run your rotor for longer

There are more options than you might think when it comes to addressing your rotor end of life. Options beyond purchasing a new rotor, moving to a new technology, or risky used and grey market options.

You need a trusted partner to navigate these options.

Benefits of rotor life extension

There are significant advantages to staying in your current technology and choosing a rotor life extension over a change in frame type or technology, most notably cost efficiency and the carbon-friendly decision to reuse versus manufacture new.

Keck Energy Libya is a non-OEM rotor option available for B/E/F class that uses OEM technology and materials. Key benefits include:

-

Cost management

-

Minimal turnaround time - no need for new permitting

-

Flexibility vs rigid OEM offering

-

Carbon-friendly (ESG friendly) by reusing existing assets vs new manufacture

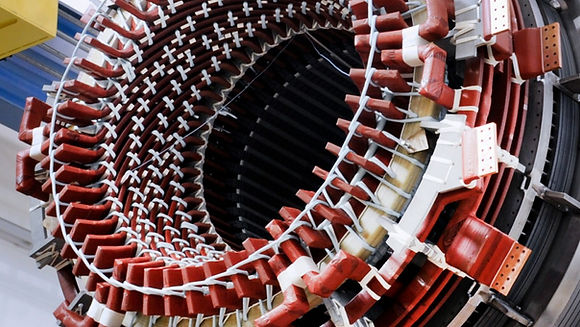

Generators

Keck Energy Libya provides an extensive range of generator services, from new stators and rotors, generator windings kits, to Generator maintenance, repair and upgrades.

Our solutions are characterized by high efficiency and the significant extension to equipment life, developed through numerous detailed analyses and optimizations.Years of operation have proved that our generators are efficient, reliable, and highly resistant to various operating conditions, and are robust in their simplicity. Our solid and resistant design guarantees many years of undisturbed operation.

Our generators and components are carried out to certified Integrated Management System standards and tailored to your specific requirements.

New generators and components

We Provide new, high-quality stators and rotors, and components for generators and their equipment, continuously improving our generators to increase reliability, improve serviceability and deliver high efficiency.

Our company supplies high-power generators ranging from 200 MW to 600 MW, along with large stators and rotors that come equipped with different cooling systems such as hydrogen, air, and water. These generators are designed to function in all types of power plants, and have been proven to be highly efficient, durable, reliable, and safe, with no instances of failure. We have gained extensive expertise and technical knowledge through our collaboration with OMEs, allowing us to offer optimal solutions to our customers.

Generators Repairs and Rewinds

At our company, we work on repairing generators and supplying their components and equipment. Our extensive inventory consists of new, refurbished, and used parts and components that not only meet but also exceed the original specifications. We ensure cost-effective options that align with your operational needs and project deadlines. As a result, we are recognized as the industry leader in generator repairs and supply.

Testing aimed at ensuring success

Our company offers comprehensive high-speed dynamic rotor balancing services in a state-of-the-art balancing room. We have the capability to simulate operating conditions and perform a wide range of tests, along with providing additional services to complement any balancing operation. Our balancer is equipped to balance rotors with a continuous flow of current through the winding.

When simulating operating conditions in the balance bunker, we conduct at-speed rotor tests to ensure the success of each recondition, repair, and/or rewind job on the rotor.

Control System Upgrades

Modern control systems enhance the performance of gas and steam turbines and associated equipment such as generators, compressors, and pumps.

Enhanced efficiency through control systems Upgrades

Efficient control systems play a critical role in the operation of both small and large turbines. At KEL, we thoroughly assess your existing system and offer a Control Package tailored to meet your specific needs. Our package is designed to significantly enhance the dependability and productivity of your equipment.

Gas and Steam Turbine systems

Our range of Systems is designed to cater to your unique requirements, providing a wide selection from comprehensive, integrated systems that cover all unit demands, to compact stand-alone systems for specialized functions such as speed governing, over-speed protection, and compressor surge control, as well as simpler applications.

Each of our systems comes with a Human Machine Interface (HMI) that features an easy-to-use display and monitoring interface, as well as alarm and shutdown protection. Furthermore, these systems offer a plethora of benefits to users, including trending, fast logging, histories, and communication utilities.

Distributed control systems

We offer a comprehensive Distributed Control System (DCS) solution for your entire facility, or can establish communication with your existing DCS using state-of-the-art communication protocols

Technical assistance

At KEL, we assist you with the procurement, design, installation, and commissioning of your system, and we establish a long-term partnership with you throughout the unit's lifecycle. Our technical support is available to provide troubleshooting and advice to optimize your operations.

Our Control packages offer numerous benefits, including increased efficiency and stability, resulting in more dependable plant operation. Moreover, the control system's troubleshooting capabilities allow for faster and easier problem resolution in the event of a failure.

Providing a turn-key solution for Power Plants on a large scale with high efficiency.

KEL offers a complete range of services to power producers, leveraging our expertise in commercial and on-site operations to seamlessly integrate all project components, from financing and engineering to design, procurement, and construction. Our independent ownership enables us to be nimble and adaptable to meet the unique needs of each project while ensuring complete accountability to our customers.

Turnkey Power Plant Engineering, Procurement, and Construction

KEL specializes in providing comprehensive solutions for power plant engineering, procurement, and construction (EPC). Our turnkey approach includes not only designing and building power plants but also providing ongoing operations and maintenance services. We oversee all aspects of the project, managing all engineering disciplines and construction trades (EPCM) to ensure a seamless process from start to finish. Additionally, our modular plant design enables us to fulfil fast-track project requirements by quickly building and deploying plants.

KEL offers a range of options for the design and operation of its facilities. Each facility can incorporate industrial and/or aeroderivative gas turbine generator sets, either for simple or combined cycle operation. In addition, KEL can include provisions in the plant design for future conversion to combined cycle operation. KEL also has expertise in installing steam turbines from a variety of Original Equipment Manufacturers (OEMs), as well as gas turbine generators that use natural gas, diesel, or alternative liquid fuels.

Storage Tanks & Petrochemical

KEL provides a comprehensive suite of services for steel storage tank projects, encompassing storage tank design, fabrication, repair, construction, and testing of fixed and floating roof tanks. Moreover, we offer supplementary services such as tank cleaning, inspection, painting, rope access, hydro-cutting, and demolition as part of our project management services. By offering a full range of services, we can seamlessly deliver your tank refurbishment requirements from inception to completion.

KEL possesses extensive experience and technical expertise in the construction of steel storage tanks. Our proficient team is capable of fabricating new storage tanks, as well as repairing and maintaining existing ones, catering to a diverse range of industries, including oil and gas, petrochemicals, and energy.

Oil and natural gas pipeline

KEL is well-equipped to undertake the complex task of installing and maintaining oil and natural gas pipeline systems while adhering to strict budgetary and timeline requirements. Our experienced crews have worked on many large oil and natural gas pipeline construction projects, laying hundreds of miles of pipeline through challenging terrain. We prioritize safety and environmental compliance, taking measures to minimize any issues.

We offer a comprehensive range of construction services for oil and natural gas pipelines, including gathering, upstream, midstream, and distribution.

Oil & Gas drill head bits

Keck Energy Libya is a leading supplier of oil and gas drill head bits, serving the needs of the oil and gas industry in Libya and beyond. They offer a wide range of drill head bits, including PDC bits, tricone bits, and diamond bits, among others, designed to meet the demands of different drilling applications. The company is known for its commitment to quality and reliability. Our exceptional customer service has enabled us to establish a loyal customer base in the industry, including some of the biggest names in the oil and gas sector

Field & Site services

As a provider of field services, Keck Energy Libya has extensive experience in servicing multiple gas and steam turbine product lines; aero-derivative, Generators light and heavy industrial gas turbines, components and accessories.

On-site repairs

Rotors, casings, fuel nozzle, and weld repairs can often be carried out during a major overhaul as direct on-site repairs.

Critical areas examined during on-site repairs include compressor blades, rotor journal, and turbine wheel conditions. In addition, Non-Destructive Testing (NDT) blades, dovetails, blade migration, and balance weight locations are all inspected to the latest OEM specifications.

Keck Energy Libya

One partner across all assets

Our aim is to help you realize your full potential and achieve outstanding results by partnering with you. We achieve this by providing support through the intricacies of your business, and ensuring that energy is not only accessible and affordable, but also sustainable.

Contact Us

Address

Mednine Street,

Off Gargaresh Road

KM7 Tripoli, Libya.

Contact

+218 21 484 234

+1(832) 492-3233

Opening Hours

Sunday - Thursday

8:00 am – 5:00 pm

Saturday

9:00 am – 2:00 pm